Product

Contact Us

- +86 17762070233

- emma@tisco-industry.com

- Mon - Fri 9:00am - 6:00pm

Products

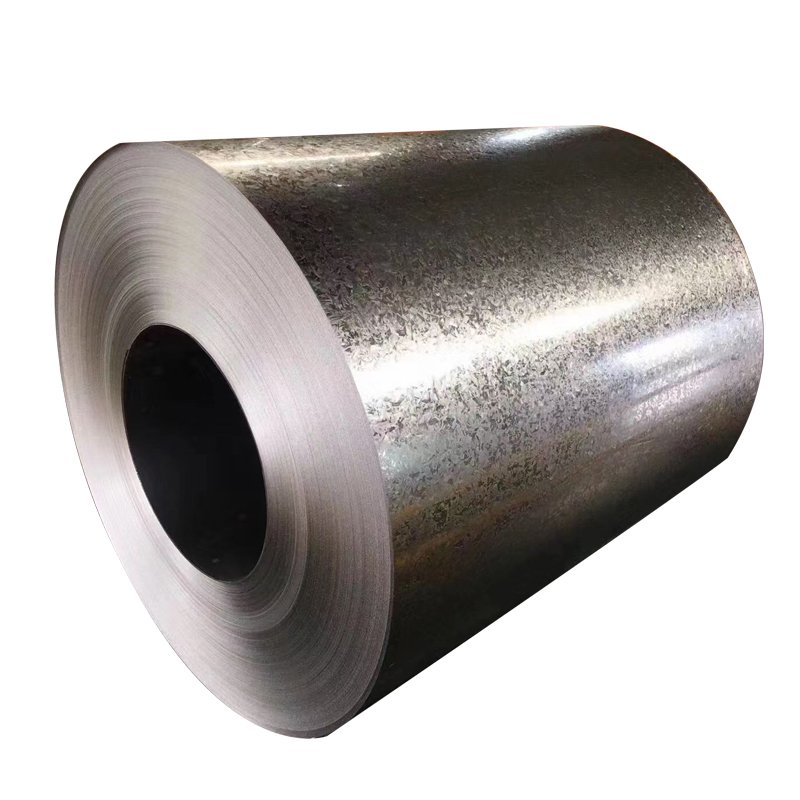

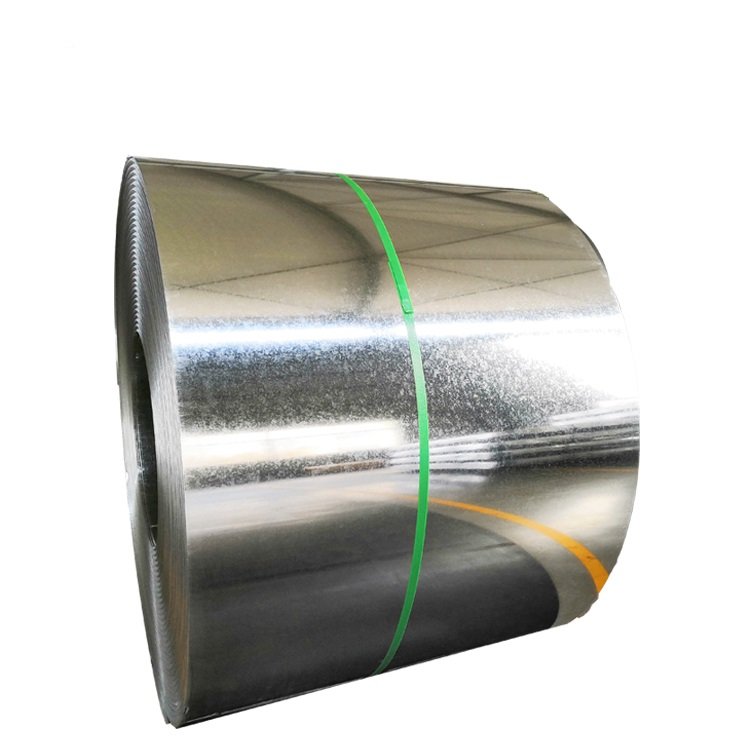

ASTM Z275 Dx51 Dx52D SGCC Hot Dipped Galvanized Steel Coil

Hot-dip galvanizing is the reaction of molten metal with an iron substrate to produce an alloy layer, thereby combining the substrate and the plating layer.

Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.

And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

———————————————————————————————————

Product Description

Additional information

| Name | Galvanized Steel Coil |

|---|---|

| Material | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, |

| Thickness | 0.12-6.00mm,or customer's requirement |

| Width | 600mm-1500mm, according to customer's requirement |

| Type of Coating | Hot Dipped Galvanized Steel(HDGI) |

| Zinc Coating | 30-275g/m2 |

| Surface | Passivation(C), Oiling(O), Lacquer sealing(L), Phosphating(P), Untreated(U) galvanized,PVC,black and color painting,transparent oil,anti rust oil |

| Lead time | 7 to 25 working days after the receipt of 30% deposit |

| Payment terms | 30%TT for deposit, 70% balance before shipment |

| Package | Standard export packaging, various transportation, according to customer needs. |

| Certificate | ISO9001 |

———————————————————————————————————

Product Details

Application areas:

It is widely used in petroleum, chemical, medical, food, light industry, mechanical instrument and other industrial pipeline and mechanical structure parts. In addition, in the same bending, torsional strength, light weight, so it is also widely used in manufacturing machinery parts and engineering structures. It is also commonly used as furniture and kitchenware, construction, kitchenware, tableware, vehicles, household appliances.

Our advantage:

(1)Quality:BKPP METAL Co.,Ltd introduces the advanced testing equipments and builds up a professional scientific research team,strictly control the quality on each steps of production. including inspection on raw materials entry, product’s color analysis during production,T-bend test, impact test, salt-spray test, tensile test and packaging testing on exported products , which ensures its integrated performance such as corrosion resistance, coating stickiness etc and the safety of transportation.

(2)Service:Nowadays, the economic globalization is facilitating international operation, our company go to many countries and regions to participate in the steel industry exhibition. our Products sell pretty well not only in domestic market, but also prevails in Europe,such as southeast Asia, Russia, Ukraine, the United States, Ireland, Singapore, Dubai, Colombia and other countries and regions, which has earned the customers trust & compliment and successfully transitioned from home to abroad.

———————————————————————————————————

Production And Processing

———————————————————————————————————

Product Packaging